Audit trails provide an electronic record of historical activities, which is invaluable for tracking assets, performing compliance inspections, or conducting preventative maintenance on equipment.

A robust audit trail logs when an activity occurred, what was done, and who performed the action. With Orca Scan, this information is automatically recorded.

How the history log works

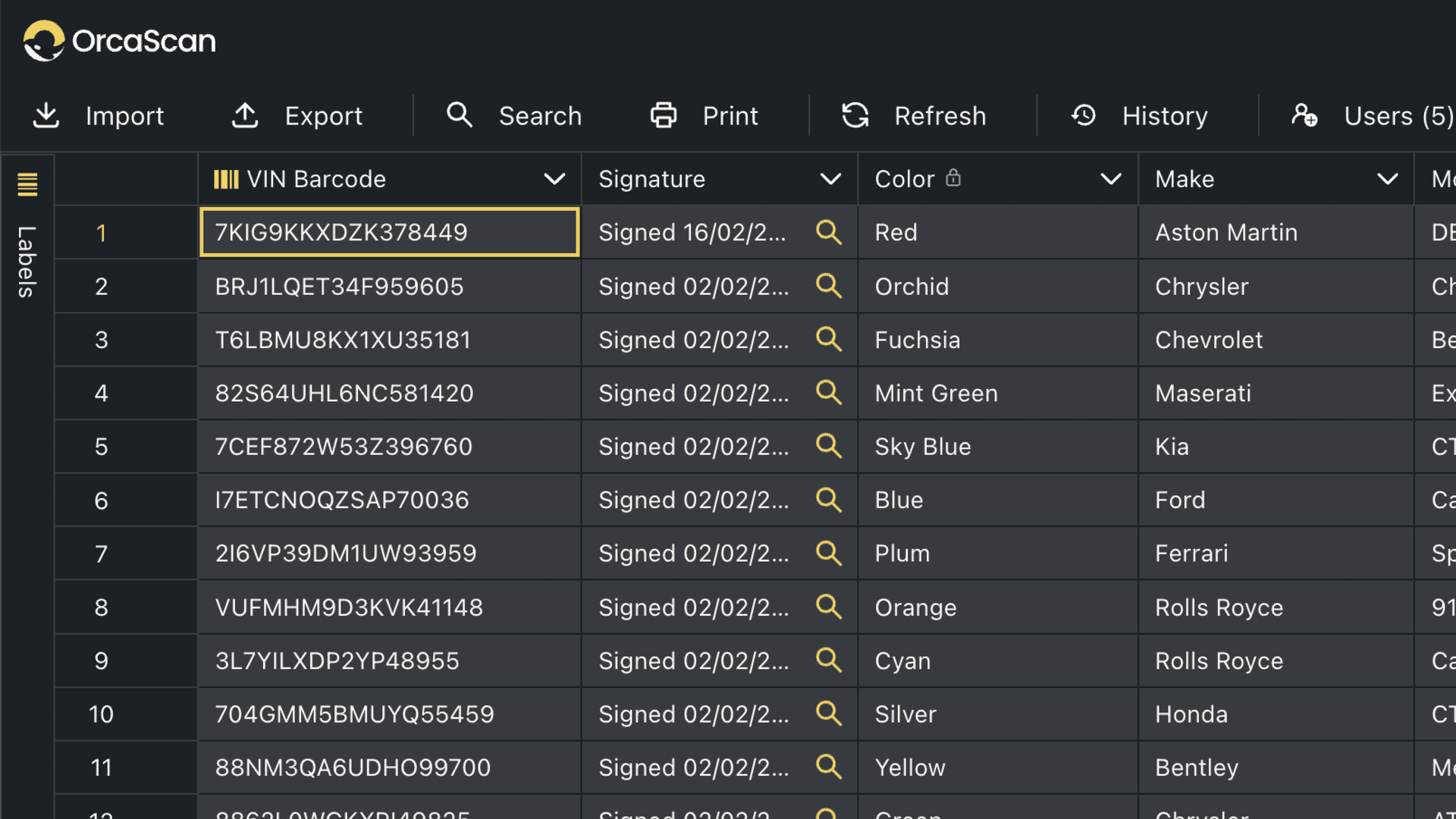

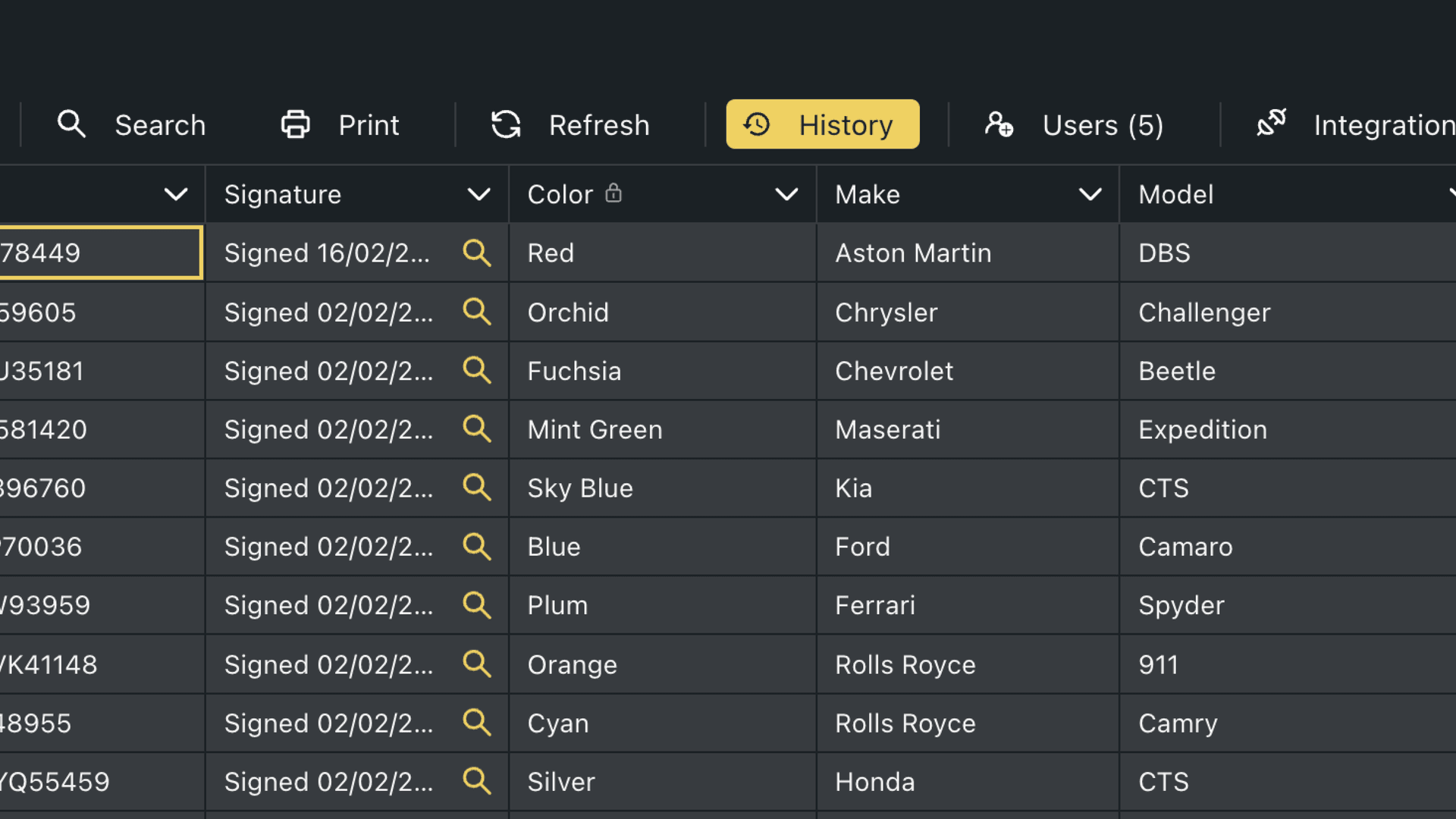

When you’re in the web application, the main view of your Orca Scan sheet displays the current status of all items and the latest changes made - this could include the last location an item was scanned, the current stock level, or in the case below, the latest servicing of industrial machines.

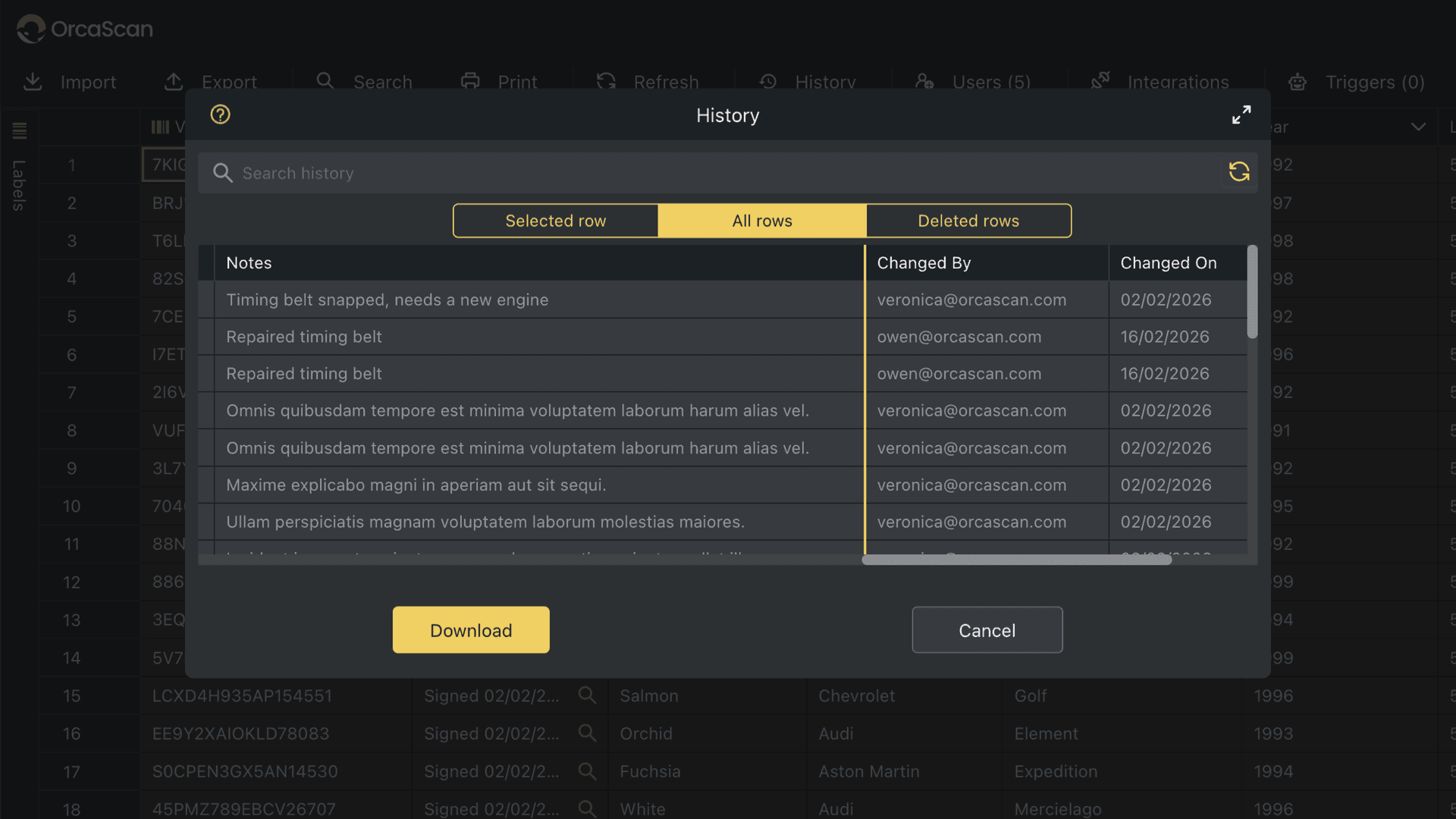

For a more detailed view, click the History button in the toolbar. This allows you to select a specific item and view a chronological record of all checks, servicing and repairs.

Whenever a barcode is scanned, the history log automatically creates records that include:

- The action performed (e.g., item created, updated)

- The timestamp of the scan and update

- The user ID and device used for the action

If you move a row (item) between different sheets, the complete history of that item is carried with it. This ensures that no historical data is lost during transfers, maintaining a comprehensive audit trail across all your sheets.

How to View the History Log for an Item in the Mobile App

In the Orca Scan mobile app, you can view the history log for a specific item by following these steps

- Open the Orca Scan mobile app

- Long-press the item in the list you want to view

- Select View History from the menu

Questions about the History Log?

We’re always happy to help, chat with us live or drop us an email.