The Falsified Medicines Directive (FMD) is a crucial EU regulation aimed at preventing counterfeit medicines from infiltrating the supply chain. This directive mandates that all pharmaceutical products for human use include a unique identifier and an anti-tampering device on their packaging. These identifiers, known as FMD barcodes, play a vital role in verifying the authenticity and traceability of medicines, thus protecting consumers from counterfeit drugs.

Why is the FMD Important?

The FMD is essential because counterfeit medicines can pose significant health risks, including harmful side effects or even death. By implementing the FMD, the EU seeks to safeguard public health and ensure patients receive genuine medications.

The FMD barcode system provides several critical benefits:

- Verification: Ensures each package is authentic before being dispensed

- Traceability: Tracks the medicine throughout the supply chain

- Consumer Protection: Anti-tampering devices guarantee packaging integrity

Impact and Relevance of FMD

All stages of the pharmaceutical industry that supply medicines, from manufacturers and wholesalers to pharmacists and hospital staff, must incorporate these safety features.

Implementing FMD barcodes has lowered the number of counterfeit medicines in the EU’s legal supply chain to approximately 0.005%. The added verification process has also contributed to fewer hospital readmissions due to medication errors.

Global Adoption of Anti-Counterfeit Measures

Countries worldwide have adopted measures similar to the Falsified Medicines Directive. Although the United Kingdom has left the European Union, it continues to uphold FMD principles to protect consumers. In the United States, the Drug Supply Chain Security Act (DSCSA) enhances the security of the drug supply chain, reflecting the objectives of the FMD.

What is the Structure of an FMD Barcode?

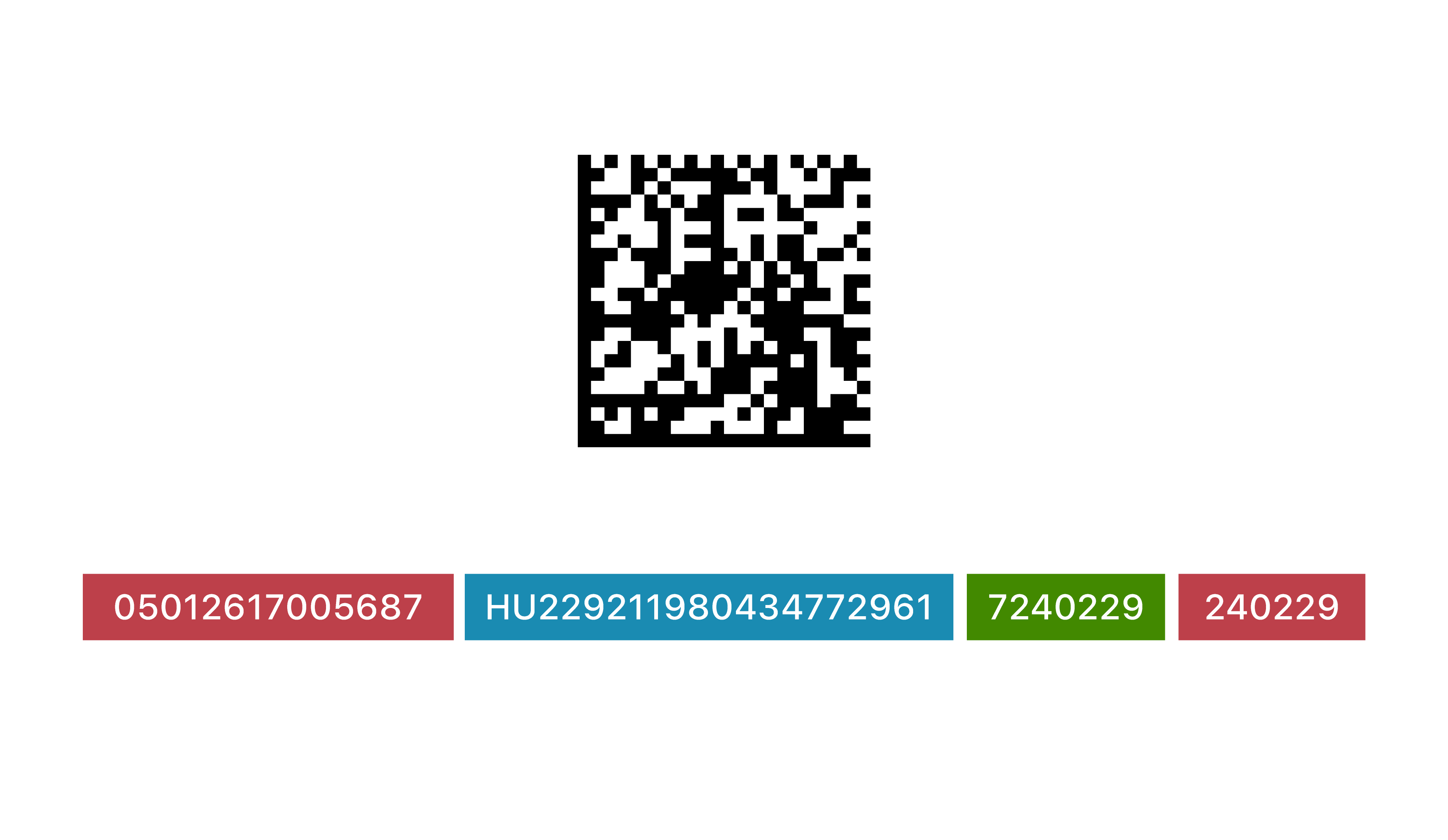

The FMD barcode is a 2D barcode in the form of a Data Matrix that encodes critical information, such as:

- Product Code: A unique identifier for each medicinal product

- Serial Number: Unique to each package

- Batch Number: Information related to the production batch

- Expiry Date: Validity period of the medicine

- National Reimbursement Number (optional): An additional identifier in some countries

Want to know what data is stored in your FMD barcode? Try our decoder.

How Do FMD Barcodes Work?

FMD barcodes are scanned and verified against a central database throughout the supply chain to verify authenticity. Here’s how the process works:

- Serialisation: Assigning a unique identifier (barcode) to each package

- Packaging: Printing the barcode, batch number, and expiry date on the package

- Verification: Scanning the barcode at various points to confirm authenticity

- Dispensing: Final verification before dispensing to the patient

Why is Traceability Important in Pharmaceuticals?

Traceability is crucial in the pharmaceutical industry, much like in blood product tracking with ISBT standards, as it ensures that every step of a medicine’s journey from manufacturer to patient is documented. This prevents counterfeit drugs from causing serious health problems, unexplained side effects, and allergic reactions.

A global operation that seized over 3 million counterfeit medicines and devices valued at over £9 million in the UK, emphasised this. According to the MHRA, robust traceability systems significantly reduce counterfeit medicines, ensuring patients receive safe treatments and maintaining trust in healthcare systems.

Practical applications of FMD barcodes

FMD legislation applies to all areas of healthcare, from manufacturing all the way through the supply chain until it is administered to a patient.

Each part of the supply chain is responsible for scanning, verifying and logging the authenticity of a medicine, for example:

- Pharmaceutical Packaging: Ensure that all products have the appropriate packaging that includes a unique identifier and is verified for the medicine within it.

- Wholesale Distribution: Monitor the movement of medicines through the supply chain by regularly scanning and logging them.

- Hospital Inventory Management and Pharmacy Dispensing: Verify the use of genuine medicines in hospitals and pharmacies before being administered to patients

- Product Recalls: Efficiently identify and recall specific batches of medicines

- Decommissioning: Mark medicines as dispensed or unavailable for sale, preventing them from being reused or resold.

To learn more about tracking FMD barcodes and the impact this can have, read how Northumbria NHS implemented a successful solution with Orca Scan.

How can I track FMD barcodes?

Orca Scan has a dedicated solution designed to decode, track and manage all of your FMD barcodes. All you have to do is:

- Download the Orca Scan mobile app

- Open the app and create a new account if you don’t already have one

- Log in and create a new sheet using the medicine barcode scanner template

- Scan the FMD barcode

The scanned FMD data will populate the relevant fields automatically, as our Drug Tracking Template easily identifies and extracts values from FMD barcodes.

Need Help with FMD Barcode Tracking?

Orca Scan is your go-to solution for decoding and managing FMD barcodes. We’re always happy to help; chat with us live or drop us an email. Make compliance easy and keep patients safe with our robust barcode tracking solutions.