Using Orca Scan, the Sacred Heart Medical Center in Washington, US, have streamlined a 5-hour a week painstaking process of tracking medical devices which combined paper forms, spreadsheets and custom software development into a 30-minute error and paper-free process.

The Cardiology Team are now able to confidently:

- Track their inventory of mechanical hearts and other medical devices, ensuring they always have sufficient medical devices on hand when their patients need them.

- Maintain audit trails from receiving the medical devices into stock, to eventually assigning them to a patient in the operating theatre.

- Build a million-dollar inventory tracking system using Orca Scan.

We had all types of typo errors, and the inventory was inaccurate half the time because we didn’t have time to sit down and manually update itDr David SatoMechanical Heart Engineer and CardiologistProvidence

Sacred Heart Medical Center is a major regional medical center featuring the best doctors, specialists and staff from all around the world.

One of them is Dr David Sato, a Senior Cardiologist leading a team of engineers at the Medical Institute Cardiology in Washington. David’s team is responsible for cardiovascular implants such as the Ventricular Assist Device which are, quite literally, saving people’s lives.

We had the privilege of talking to David about how his team meet the needs of their patients by tracking their inventory of mechanical hearts and other medical devices.

I use Orca Scan to track a million-dollar inventoryDr David SatoMechanical Heart Engineer and CardiologistProvidence

David explained how important it is that his team monitor their inventory levels to ensure they always have sufficient medical devices on hand when their patients need them.

Maintaining audit trails from receiving the implants into stock, to eventually assigning them to a patient in the operating theatre, is of equal importance; “We use Orca Scan to record which devices have been assigned to which patient”.

How it used to work

To accomplish this for the dozens of devices received daily, they:

- Wrote down the serial numbers on paper forms at arrival

- Manually entered them into a spreadsheet at the end of each day

- Ran a custom-written software program to retrieve product information for each device

- Manually updated each item in the spreadsheet as it was assigned to a patient

Combining paper forms, spreadsheets and custom software development were painful. It required lots of manual checks to reduce the potential error rate from manually entering serial numbers and would consume around 5 hours per week.

Time for a change

The unreliability of the process and the time it consumed, made it clear to David that he needed to find a more efficient solution - so he started on the App Stores.

“I tried several apps, but Orca Scan was the most reliable at reading all types of barcodes. The way it handles the data and automatically uploads was great.”

How it works now

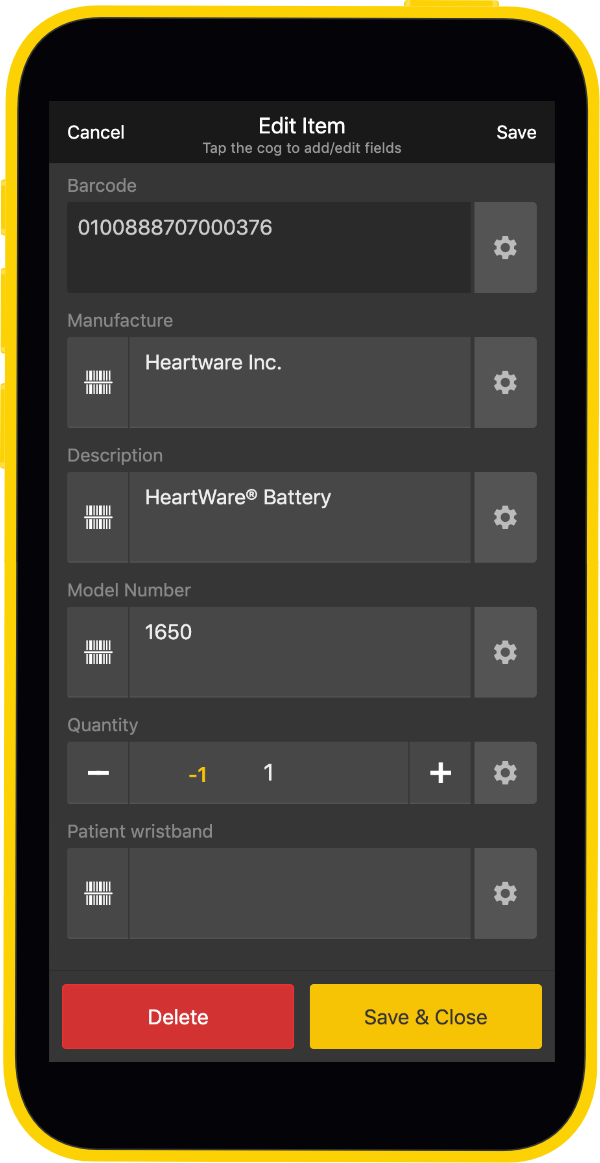

David and his team now use Orca Scan to track their inventory. Their new process looks like this:

- Scan the barcode on each device as they are received

- Add the quantity - (date and time assigned automatically)

- Scan the item and assign the patient ID before implant

- And upload to master inventory sheet

It would take 5 hours a week to do this process manually - it’s down to 30 minutesDr David SatoMechanical Heart Engineer and CardiologistProvidence